Protecting the Global Environment with Japanese Technology!

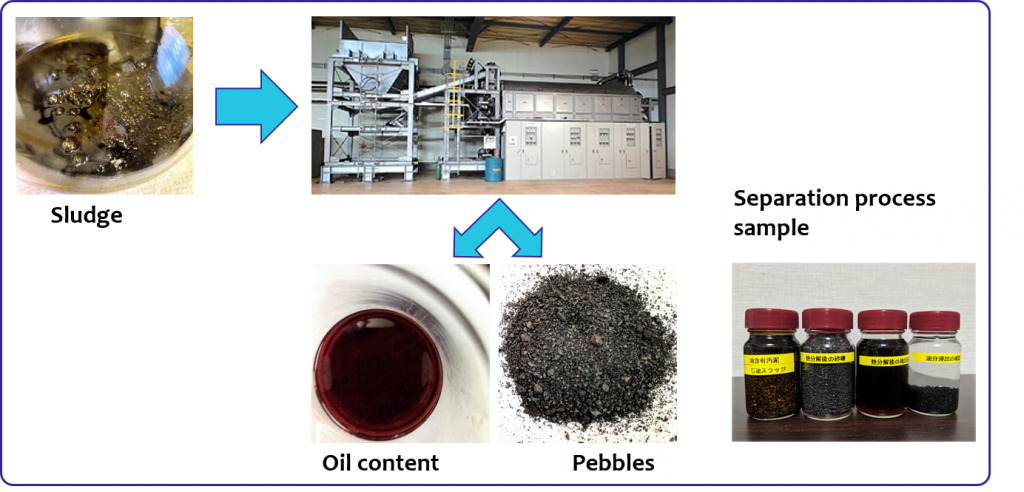

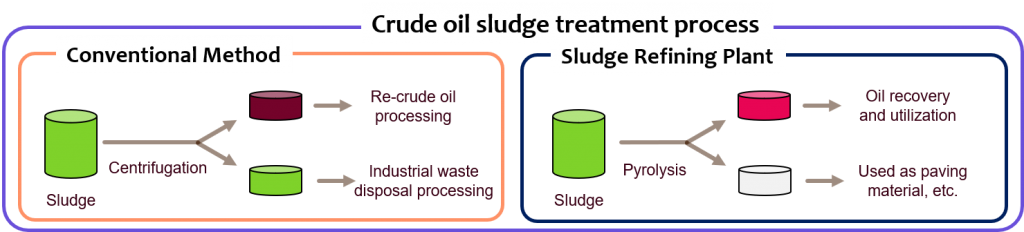

Thermal decomposition of sludge enables complete separation of oil from sand and gravel, which is not possible with conventional centrifugal separation methods!

The sludge that accumulates at the bottom of crude oil tanks is a mixture of asphaltene, wax, moisture, sand and gravel, and rust contained in the crude oil.

The amount of oil contained in crude oil varies depending on where it is produced, but it is said to exceed 10% of the storage tank capacity when deposited, and is regularly discharged and disposed of as industrial waste at great expense.

In the crude oil sludge oiling plant, the oil is vaporized and separated by pyrolysis treatment, and then liquefied and recovered to separate the oil from sand and gravel.

- Improved oil recovery rate due to complete separation of oil and sand and gravel

- Recovered oil is recycled into crude oil

- De-oiled sand and gravel can be used as paving material and landfill material

- Reduction of industrial waste volume of sludge and reduction of disposal costs

Use of storage tanks for purposes other than processing crude oil sludge

- Treatment of sludge deposited at the bottom of tankers and COW (Crude Oil Washing)

- Treatment of crude oil sludge and soil containing crude oil sludge discharged and left in oil fields, etc.

- Separation and treatment of extra heavy oil and its contents, etc.